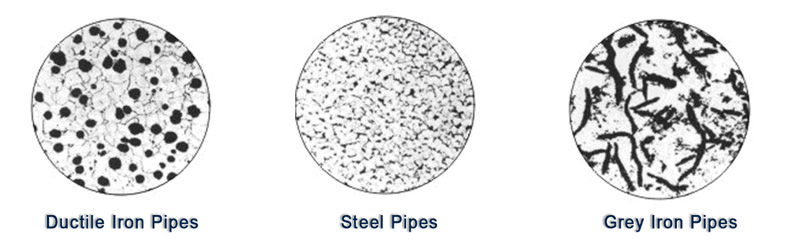

Ductile Iron: A Superior Modern Material

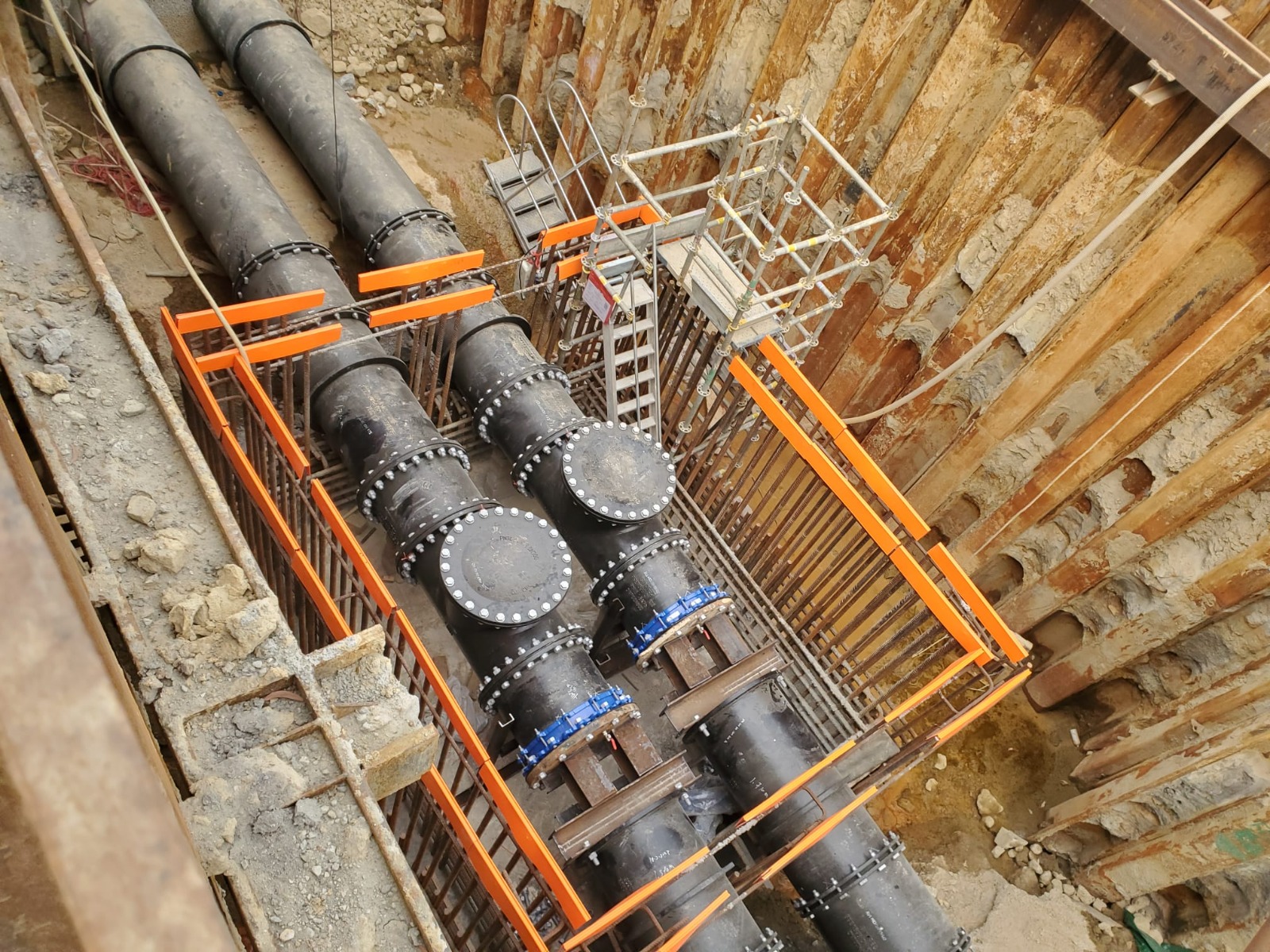

SINOTEC ductile iron pipes and fittings are well-approved by the Water Supplies Department, Drainage Services Department, Civil Engineering and Development Department, MTR Corporation and Airport Authority in Hong Kong. Their products are widely utilized in critical infrastructure projects, including:

- Kwu Tung North New Development

- Tung Chung New Town Extension

- Hung Shui Kui Ha Tsuen New Development

- Tseung Kwan O-Lam Tin Tunnel

- Sai Sha Road Widening

- Dong Jiang Water Mains

- Term Contract for Waterworks

- Sewage Pumping Station

Key benefits

- Complete System Solutions – A full range of pipes, fittings, valves, and accessories ensures seamless integration for water, sewage, and gas applications.

- Reliable, Leak-Free Performance – Engineered joint systems deliver long-term durability and tight seals.

- Exceptional Strength & Resilience – Ideal for high-stress environments, ductile iron withstands fatigue, pressure surges, ground subsidence, and third-party damage.

- Cost-Efficient Installation

- Simple and quick assembly, requiring no specialized tools or skilled labor.

- Compatible with narrow trenching, reducing installation and reinstatement costs.

- Long service life ensures a cost-effective investment.

- Advanced Protection Systems – Customizable internal and external linings adapt to varying soil conditions and fluid types.

- Versatile Applications

- Large-diameter transmission and distribution mains.

- Small-diameter urban distribution networks.

- Water and sewage treatment plants.

- Pipeline rehabilitation via narrow trenching.

Jointing Systems

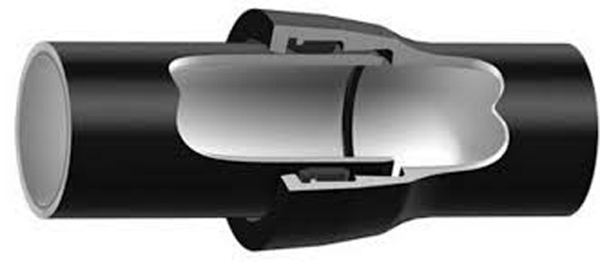

- Tyton® Flexible Joint (Standard for Water Pipelines)

- Fast, easy installation.

- Maintains performance even under angular deflection and longitudinal movement.

- For detailed specifications, refer to the product catalogue.

- Flanged Joint (Rigid & Self-Anchoring)

- Designed for above-ground use in pumping stations, treatment plants, and industrial piping.

- Also suitable for underground ancillary fittings (e.g., valves, hydrants).

- Note: Buried flanges require corrosion protection (e.g., protective tape on bolts).

Coatings and Linings

- Ductile iron pipes and fittings are available with a selection of high-performance external coatings and internal linings, designed to withstand diverse ground conditions, water types, and above-ground environments (e.g., pumping stations).

- All coatings and linings comply with British, European, and International standards (BS EN 545, BS EN 598, BS 4027, BS 3416, ISO 8179) and are certified for potable water and sewage applications.

External Coatings

- SINOTEC provides a variety of external coating systems tailored to different soil conditions.

- Standard Pipe Coating: Zinc + Bitumen

- Zinc is a globally proven protective coating for pipelines. A 200g/m² zinc layer offers superior defense against most soil types, functioning in two key ways:

- Barrier Protection – Beneath the bitumen coating, the zinc gradually forms a tightly bonded protective layer on the iron surface.

- Self-Healing Protection – If damaged during handling or installation, adjacent zinc acts as a sacrificial anode, shielding exposed iron until a natural layer of zinc corrosion products seals the affected area.

Enhanced Zinc Protection (200g/m² vs. Standard 130g/m²)

- SINOTEC exceeds the BS EN 545 requirement (130g/m²) by applying a minimum 200g/m² zinc coating, delivering two major advantages:Extended Active Protection Period – The zinc remains effective for significantly longer.

- Stronger, Denser Protective Layer – The resulting zinc transformation layer is thicker and more resilient.

Internal Linings

The standard internal lining for SINOTEC Ductile Iron pipes and fittings is CEMENT MORTAR. Sulphate Resistant Cement Mortar to BSEN545 and BSEN197-1 are commonly used in Fresh water and salt Water application. While internal Fusion bond epoxy powder coating is also available for both Pipes and fittings. For sewerage pipeline in which the water corrosivity is highly aggressive , internal high alumina cement mortar lining to BSEN598 is commonly used.

For Water Supples Department project in Hong Kong, the standard coatings and linings for ductile iron pipes are external zinc plus bitumen coating and internally lined with sulphate Resistant cement mortar plus minimum 150 micron epoxy seal coat. While for ductile iron fittings, they are internally and externally coated with fusion bond epoxy powder coating. For Drainage Services Department, the internal lining is high alumina cement and the external coating is zinc plus bitumen for ductile iron pipes and fittings.